Ankur Shah of Krishna Defence and Allied Industries Limited on Indigenous Manufacturing, Design-Led Defence Engineering, and Building Mission-Ready Capabilities

📝Interviews

StartupTalky presents Recap'25, a series of exclusive interviews where we connect with founders and industry leaders to reflect on their journey in 2025 and discuss their vision for the future.

In this edition of Recap’25, StartupTalky speaks with Ankur Shah, Managing Director of Krishna Defence and Allied Industries Limited, who reflects on India’s accelerating push toward self-reliance in defence manufacturing and the growing importance of design-led, mission-critical engineering. Shah shares how the defence ecosystem in 2025 is being shaped by higher indigenisation targets, rising investments in R&D, and the need for technologically advanced, compliance-driven manufacturing capabilities that can perform under extreme operational conditions.

He goes on to discuss how Krishna Defence has evolved from a manufacturing partner into a solution-driven contributor to India’s defence preparedness, combining in-house R&D, metallurgical expertise, and multi-stage quality systems. The conversation explores the impact of the Make in India initiative, the shift toward smart weapons and advanced platforms, regional defence corridors, and the company’s roadmap for expanding across naval, land, aero, and underwater systems—while maintaining the trust, precision, and credibility required in strategic defence programs.

StartupTalky: What does your company do? What was the motivation/vision with which you started?

Ankur Shah: At Krishna Defence and Allied Industries Limited, we design, develop, and manufacture mission-critical steel and engineering components for India’s defence platforms, including naval vessels and armoured systems. India’s self-reliance goals by developing mission-ready components backed by in-house R&D, multi-stage inspection protocols and metallurgical expertise.

The vision behind starting Krishna Defence was based on strengthening India’s self-reliance in strategic manufacturing. At a time when critical defence components were heavily import-dependent, the goal was to build indigenous capabilities backed by deep metallurgical expertise, in-house R&D, and robust quality systems. Our motivation has always been to move beyond conventional manufacturing and become a design-led, solution-driven partner to the Armed Forces, contributing meaningfully to India’s defence preparedness and long-term strategic autonomy.

StartupTalky: What is/are the USP/s of your products?

Ankur Shah: Our USP lies in our ability to provide defence-grade, mission-ready components that combine metallurgical depth with design-led manufacturing. We support India’s self-reliance goals by supporting in-house R&D, multi-stage inspection protocols and quality assurance protocols. This end-to-end control ensures consistent performance under extreme operational conditions. Furthermore, our ability to develop custom solutions for both naval and land platforms, along with the capacity to deliver large quantities while maintaining compliance with the stringent defence standards, positions us as a trusted, long-term partner rather than just a component supplier.

StartupTalky: How has the industry you are in changed in recent years, and how has your company adapted to these changes?

Ankur Shah: The defence and allied manufacturing sectors have undergone major changes and have shifted significantly towards a self-reliant India. 65% of the defence equipment is being produced in India, which is a clear indication of the successful implementation of the Make in India initiative. Along with increased demand and a bigger focus on R&D, quality, traceability and compliance, there is also a rising requirement for smart weapons, a stronger push towards military technology, including investment in R&D, and technology-intensive platforms. We have, therefore, aligned with these changes by enhancing our internal R&D, ramping up special-grade steel and precision fabrication capabilities, and making a substantial investment in advanced testing, domestic prototyping, and design-led manufacture to deliver mission-ready, future-focused military solutions.

StartupTalky: What key metrics do you track to check the company's growth and performance?

Ankur Shah: Our company, just like every other company, tracks the order booking, invoicing and EBIT levels hawkishly. The typical programme cycles and product development cycles in our sector are quite long. So on the operations end, as well as the product development, we utilise metrics more in sync with our customers' programme management requirements.

We focus on the implementation of quality standards, viz, ISO, AS9100, DNV, IRS, as well as all the applicable protocols that are part of our interactions with the DRDO labs and defence sector establishments.

StartupTalky: What were the most significant challenges your company faced in the past year, and how did you overcome them?

Ankur Shah: Over the last year, we have had a few challenges. Stricter compliance regulations and the increased difficulty of defence projects demanding faster deliveries and greater precision at the same time were among these challenges. The products that we manufacture require a unique skill set; there is no ready availability of such manpower. Hence, we had to train our manpower and team for these special skills. Because of the supply chain instability and the fluctuation of the technical specifications, it was necessary to quickly adapt to the changes.

We dealt with these challenges by creating and maintaining strong strategic alliances with the vendors, refining our processes, and training our workforce in-house in the areas of steel processing, precision machining, and quality assurance. In addition, we continued our perpetual investment in R&D, workforce shifting, and multi-stage inspection systems that together were instrumental in maintaining quality and reliability. By planning our operations systematically, futuristically, and strategically, we were able to complete our tasks within the time frame and at the same time successfully meet the Indian Armed Forces' demanding requirements.

StartupTalky: What are the different strategies you use for marketing? Tell us about any growth hack that you pulled off.

Ankur Shah: At Krishna Defence, the marketing strategy is built around credibility, relationships, and technical leadership rather than conventional promotion. We are going to focus on the long-run interaction with the Armed Forces, PSUs and strategic partners via direct outreach, industry forums and participation in defence exhibitions. One of the main ways we have been growing our business is through taking the position of a design-led solution partner rather than a component supplier, which has allowed us to get into more valuable programs. This method, together with quick performance and referrals in the defence community, has resulted in continuous growth and repeat sales.

StartupTalky: What opportunities do you see for future growth in your industry in India and the world? What kind of difference in market behaviour have you seen within states in India?

Ankur Shah: Higher defence budgets, indigenisation demands, and the increasing need for advanced combat platforms, autonomous systems, and niche materials are some of the factors that fuel the defence industry sector's growth potential in India as well as globally. India's push for defence exports and strategic partnerships further opens up the international market for Indian companies. Different states in India behave differently as markets; well-established defence corridors like Gujarat and Uttar Pradesh show faster project implementation and supplier engagement, whereas developing states focus on skill development and capacity building. These regional differences, which also enable us to diversify into both domestic and international defence markets, pave the way for localisation, co-operation, and scalable manufacturing models.

StartupTalky: How do you plan to expand the customer, product, and team base in the future?

Ankur Shah: We participate in various industry forums, viz CII and SIDM, where there is a good deal of brainstorming on the new initiatives coming up in the ecosystem. Product-led innovation and growth have been our forte. We have been fortunate that the defence establishments value this and engage us for complex developmental projects right from the ideation stages.

We continue to work on new project enquiries in our existing domains of metallurgical products, electronic systems, as well as the underwater domain awareness. Parallely, we are expanding our engineering team through lateral hires as well as fresh talent scouting in universities. Both these efforts are focused towards growth in our existing programs as well as forays into aero systems and land systems.

KDAIL is well poised to inorganically grow its product portfolio through its strategic investments in startups, MSMEs, as well as JVs with foreign OEMs.

StartupTalky: One tip that you would like to share with people reading this article who want to get into entrepreneurship?

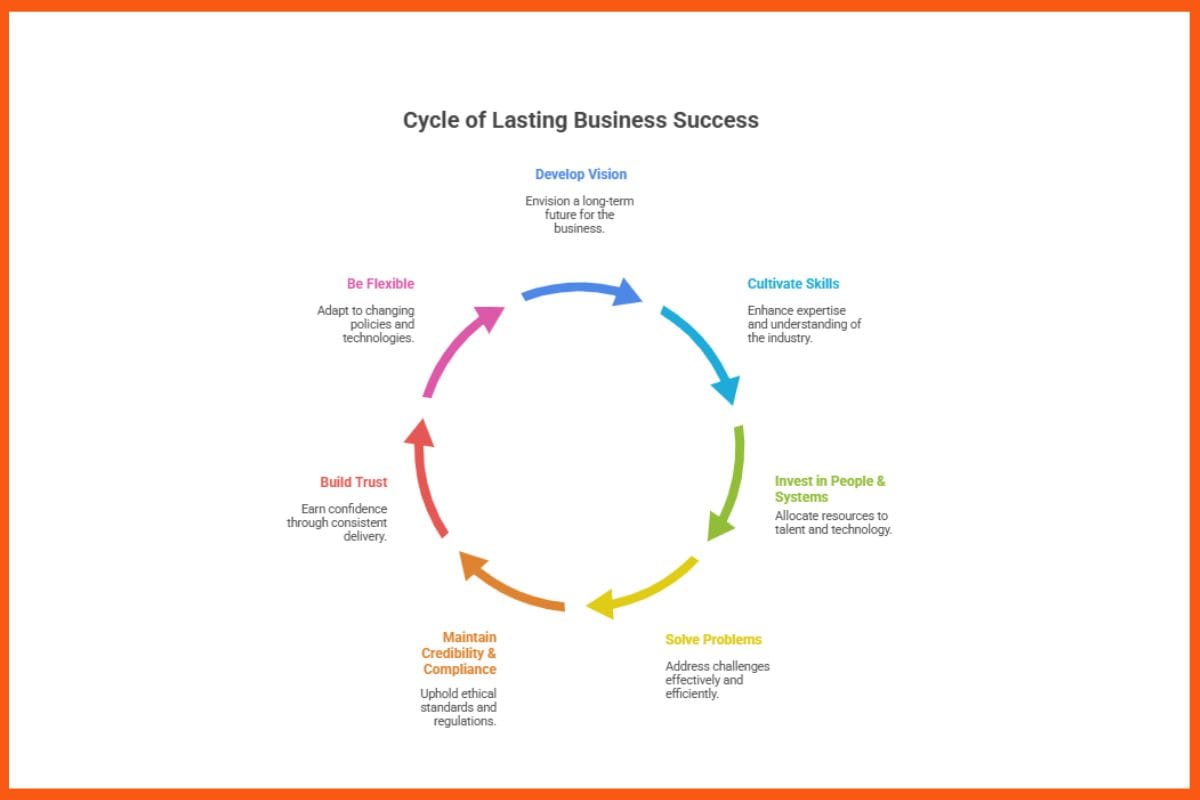

Ankur Shah: If someone is thinking of starting a business of their own, especially in industries such as defence manufacturing, they need to be very disciplined, have a vision that looks far beyond the future, and patiently develop their skills and understanding of the environment in which they operate. Put money into people and top-notch systems, focus on solving problems, and don't ever let your credibility or compliance be sacrificed. Trust, which is the result of delivery and consistency, is therefore obtained gradually. Don't stick to your core principles only; be flexible as well, since policies and technologies may change. The secret to lasting success is not temporary victories but the gradual development of competencies that will last forever.

Explore more Recap'25 interviews here.

Must have tools for startups - Recommended by StartupTalky

- Convert Visitors into Leads- SeizeLead

- Website Builder SquareSpace

- Run your business Smoothly Systeme.io

- Stock Images Shutterstock